Scientists patent corrosion-resistant nano-coating for metals

Thinner, less toxic than existing coatings; efficient and economical to produce

Scientists at the U.S. Department of Energy's Brookhaven National Laboratory have developed a method for coating metal surfaces with an ultrathin film containing nanoparticles which renders the metal resistant to corrosion and eliminates the use of toxic chromium for this purpose. The scientists have been awarded U.S. Patent number 7,507,480 for their method and the corrosion-resistant metals made from it. The technology is available for licensing.

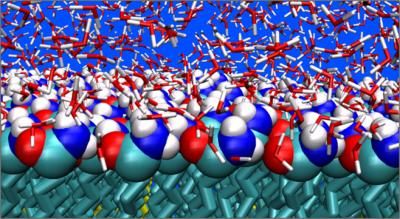

"Our coating is produced right on the metal using a simple two- or three-step process to produce a thin film structure by crosslinking among the component compounds," said chemist Toshifumi Sugama, a guest researcher at Brookhaven Lab. "The result is a layer less than 10 nanometers thick that protects the metal from corrosion, even in briny conditions."

Corrosion resistance is essential for metals used in a wide range of applications, from electronics to aviation to power plants. Traditionally, compounds containing a toxic form of chromium have provided the best corrosion resistance. Scientists looking to develop chromium-free alternatives have been unable to achieve the thin layers desirable for many applications. "Ultrathin coatings reduce the amount of material needed to provide corrosion resistance, thereby reducing the cost," Sugama explained.

Sugama's approach achieves several goals - low toxicity and excellent corrosion resistance in a film measuring less than 10 nanometers that can be applied to a wide array of metals, including aluminum, steel, nickel, zinc, copper, bronze, and brass. According to Sugama, the coating should be of specific interest to industries that produce coated valves, pumps, and other components, as well as the manufacturers of aluminum fins used in air-cooled condensers at geothermal power plants, where preventing brine-induced corrosion is a high priority.

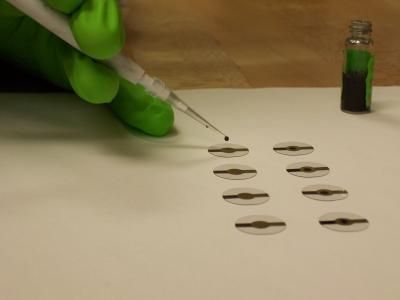

The coating can be made in a variety of ways suited to a particular application. In one embodiment, it starts as a liquid solution that can be sprayed onto the metal, or the metal can be dipped into it. The metal is then subjected to one or more treatment steps, sometimes including heating for a period of time, to trigger cross-linking reactions between the compounds, and simultaneously, to form corrosion-inhibiting metal oxide nanoparticles, such as environmentally benign cerium-based oxides.

"Among the key factors that ensure the maximum corrosion-mitigating performance of these ultrathin coating films are the great water-repellency, the deposition of metal oxide nanoparticles over the metal's surface, and their excellent adhesion to metal. The combination of these factors considerably decreased the corrosion of metals," said Sugama.

The corrosion resistance of these coatings can be comparable, and even superior, to chromium-based coatings, he said. In fact, these new coatings provide even better coverage of metal surfaces than chromium coatings. Sugama added, "This is particularly advantageous when the metal to be coated possesses fine structural detail."

Because the method deposits such a thin coating of material, it is highly economical and efficient.

Most read news

Other news from the department science

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.