Shining a light on damage within polymers

When it comes to even the most advanced materials, the adage "if it does not bend, it breaks" is often true. But before that final snap, most materials experience microscopic damage that could be fixed -- but only if you know it's there. In a study researchers introduce a new technique that detects and illuminates damage in various types of materials.

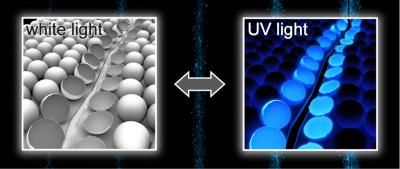

Embedded within polymers, microcapsules filled with aggregation-induced emission dyes break open when the surface is scratched; the resulting fluorescence allows researchers to detect the damage quickly and with high sensitivity.

American Chemical Society

Microscopic damage eventually leads to failure in polymers and composite materials, but it is difficult to detect without the aid of specialized equipment. Previously reported methods rely on chemical reactions or multicomponent systems to identify problems and are not generalizable over a wide range of applications and materials. In addition, many use color changes that are difficult to detect within the context of the objects in which they are embedded. To address these issues collectively, Jeffrey Moore, Nancy Sottos and colleagues envisioned a simple, single-component fluorescence system that would glow in response to microscopic damage.

The authors took advantage of a type of fluorescence called aggregation-induced emission (AIE). As opposed to most fluorescent dyes, the light emitted from AIE dyes becomes brighter as they solidify out of solution. To use AIE as a reporting strategy, the researchers created microcapsules containing solutions of AIE dyes and embedded them in a polymer. When they scratched the material's surface, the capsules broke and released the dye solution, causing the damaged region to glow blue under UV light as the liquid quickly evaporated. The researchers demonstrated that their method works for various materials and for different types of damage including a cut only 2 ?m wide, far smaller than could be seen with the naked eye. The authors propose that simple systems such as this one could reduce costs associated with routine inspection and pre-scheduled replacement of parts.

Original publication

Most read news

Original publication

Maxwell J. Robb, Wenle Li, Ryan C. R. Gergely, Christopher C. Matthews, Scott R. White, Nancy R. Sottos, and Jeffrey S. Moore; "A Robust Damage-Reporting Strategy for Polymeric Materials Enabled by Aggregation-Induced Emission"; ACS Central Science; 2016

Topics

Organizations

Other news from the department science

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.