New world record in materials research - X-ray microscopy with 1000 tomograms per second

"This method opens a door for the non-destructive study of fast processes in materials, which is what many research groups and also industry have been waiting for"

tomoscopy is an imaging method in which three-dimensional images of the inside of materials are calculated in rapid succession. Now a team led by HZB physicist Francisco García Moreno has achieved a new world record at the TOMCAT beamline of the Swiss Light Source at the Paul Scherrer Institute: with 1000 tomograms per second, it is now possible to non-destructively document very fast processes and developments in materials on the micrometre scale, such as the burning of a sparkler or the foaming of a metal alloy for the production of stable lightweight materials.

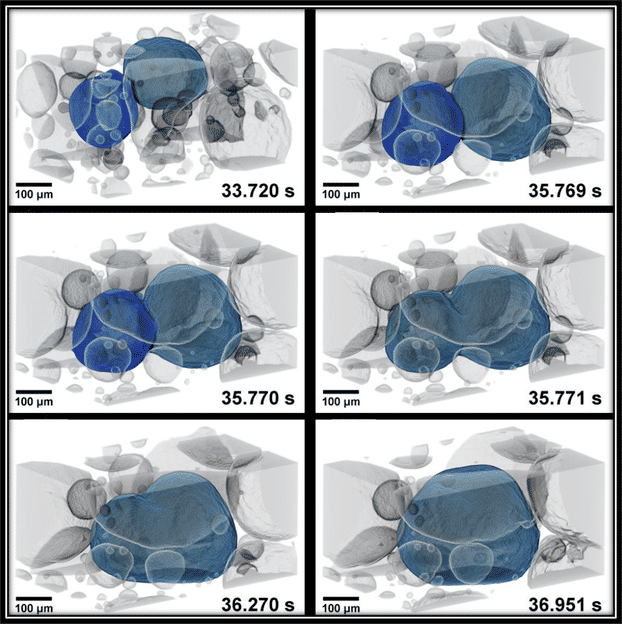

Such metal foams based on aluminium alloys are being investigated as lightweight materials, for example for the construction of electric cars. The morphology, size and cross-linking of the bubbles are important to achieve the desired mechanical properties such as strength and stiffness in large components.

© Adv. Mat./PSI/HZB

Most people are familiar with computed tomography from medicine: a part of the body is X-rayed from all sides and a three-dimensional image is then calculated, from which any sectional images can be created for diagnosis.

Fast 3D-images with synchrotron radiation

This method is also very useful for material analysis, non-destructive quality testing or in the development of new functional materials. However, to examine such materials with high spatial resolution and in the shortest possible time, the particularly intense X-ray light of a synchrotron radiation source is required. In the synchrotron beam, even rapid changes and processes in material samples can be imaged if it is possible to acquire 3-dimensional images in a very short time sequence.

From 200 to 1000 tomograms per second

An HZB team led by Dr Francisco Garcia Moreno is working on this together with colleagues from the Swiss Light Source SLS at the Paul Scherrer Institute (PSI), Switzerland. Two years ago, they managed a record 200 tomograms per second, calling the method of fast imaging tomoscopy. Now the team has achieved a new world record: with 1000 tomograms per second, they can now record even faster processes in materials or during the manufacturing process. This is achieved without any major compromises in the other parameters: the spatial resolution is still very good at several micrometres, the field of view is several square millimetres and continuous recording periods of up to several minutes are possible.

Rotary table and high speed camera

For the X-ray images, the sample is placed on a high-speed rotary table developed in-house, whose angular speed can be perfectly synchronised with the camera's acquisition speed. "We used particularly lightweight components for this rotary table so that it can reach 500 Hertz rotation speed stably," García Moreno explains.

At the TOMCAT beamline at the SLS, which is specialised in time-resolved X-ray imaging, PSI physicist Christian Schlepütz used a new high-speed camera and special optics. "This increases the sensitivity very significantly, so that we can take 40 2D projections in one millisecond, from which we create a tomogram," Schlepütz explains. With the planned SLS2.0 upgrade, even faster measurements with higher spatial resolution should be possible from 2025.

Processing the data stream

The acquisition of 1000 three-dimensional data sets per second - and this over a period of minutes - generates a huge data stream, which was initially stored at the PSI. Finally, Dr. Paul Kamm at HZB was responsible for the further processing and quantitative evaluation of the data. The reconstruction of the raw data into 3D images was carried out remotely from HZB on the high-performance computers at PSI, and the results were then transferred to HZB for further analysis.

Sparklers, dendrites and bubbles

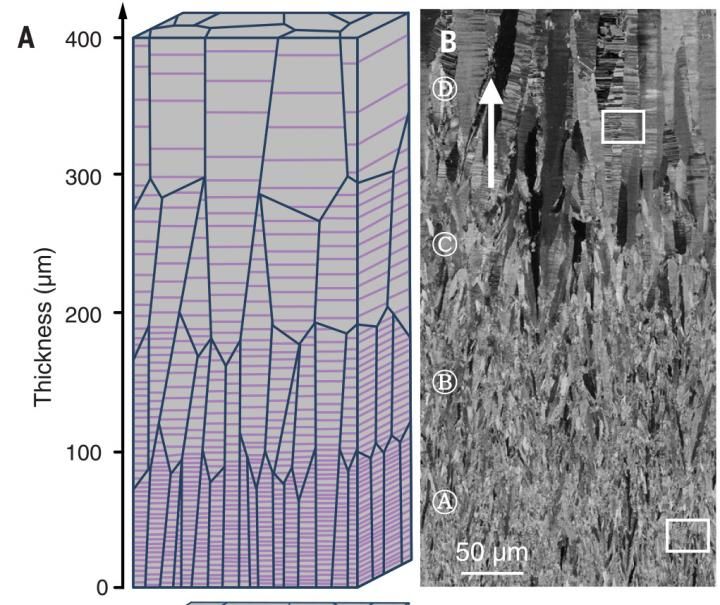

The team demonstrated the power of tomoscopy with various examples from materials research: The images show the extremely rapid changes during the burning of a sparkler, the formation of dendrites during the solidification of casting alloys or the growth and coalescence of bubbles in a liquid metal foam. Such metal foams based on aluminium alloys are being investigated as lightweight materials, for example for the construction of electric cars. The morphology, size and cross-linking of the bubbles are important to achieve the desired mechanical properties such as strength and stiffness in large components.

"This method opens a door for the non-destructive study of fast processes in materials, which is what many research groups and also industry have been waiting for," says García Moreno.