Sensing pressure using paper

“The future applications of this device are limited only by our imagination”

Several industrial, automotive, and healthcare applications rely on accurate and precise measurement of pressure. Flexible and wearable pressure sensors are typically fabricated using petroleum-based polymers. The solid waste generated from using such non-biodegradable plastics is harmful for the environment. To avoid this issue, researchers at the Indian Institute of Science (IISc) have now fabricated pressure sensors that use paper as the medium.

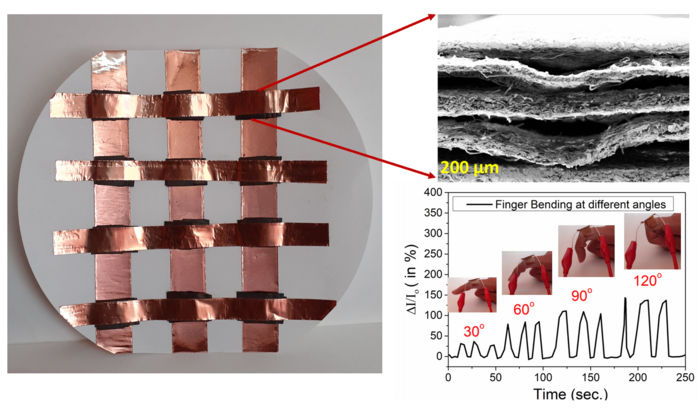

Wearable paper pressure sensor

Neha Sakhuja

A pressure sensor detects physical pressure and converts it into an electrical signal that is displayed in the form of a number indicative of its magnitude. Nowadays, paper-based electronic devices are gaining greater attention owing to their natural biodegradability, excellent flexibility, porous fibrous structure, light weight, and low cost. However, paper-based sensors developed so far have certain disadvantages.

“In any sensor, there is always a trade-off between sensitivity and dynamic range. We want to have high sensitivity. Sensitivity is essentially a measure of the smallest entity (amount of pressure) that we can detect. And we want to sense that quantity over an extensive range,” says Navakanta Bhat, Professor at the Centre for Nano Science and Engineering (CeNSE) and corresponding author of the paper published in the ACS Sustainable Chemistry & Engineering. His team has proposed a design for the paper sensor that, by virtue of its structure and multilayering, achieves high sensitivity and can detect a broad range of pressures (0-120 kPa) with a response time of 1 millisecond.

The sensor is made of plain and corrugated cellulose papers coated with tin-monosulfide (SnS) stacked alternatively to form a multi-layered architecture. SnS is a semiconductor that conducts electricity under specific conditions. “Paper in itself is an insulator. The major challenge was choosing an appropriate 3D device structure and material to give conductive properties to paper,” says Neha Sakhuja, a former PhD student at CeNSE and the first author of the paper.

When pressure is applied on the sensor’s surface, the air gaps between the paper layers decrease, increasing the contact area between these layers. Higher contact area leads to better electrical conductivity. On releasing the pressure, the air gaps increase again, thus decreasing the electrical conduction. This modulation of the electrical conductivity drives the sensing mechanism of the paper sensor.

“Our key contribution is the simplicity of the device. It is like creating paper origami,” explains Bhat.

The sensor shows promise in being developed into a flexible and wearable electronic device, especially in the healthcare sector. For example, the research team mounted it onto a human cheek to investigate the motion involved in chewing, strapped it to an arm to monitor muscle contraction, and around fingers to track their tapping. The team even designed a numeric, foldable keypad constructed using the in-house paper-based pressure sensor to demonstrate the device’s usability.

“The future applications of this device are limited only by our imagination,” says Bhat. “We would [also] like to work on increasing the stability and durability of these sensors and possibly collaborate with industries to manufacture them in large numbers.”

Original publication

Other news from the department science

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.