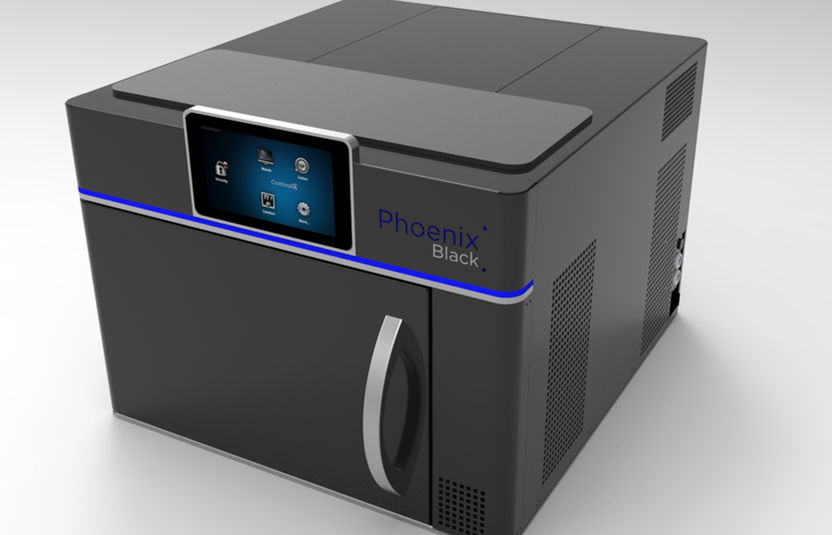

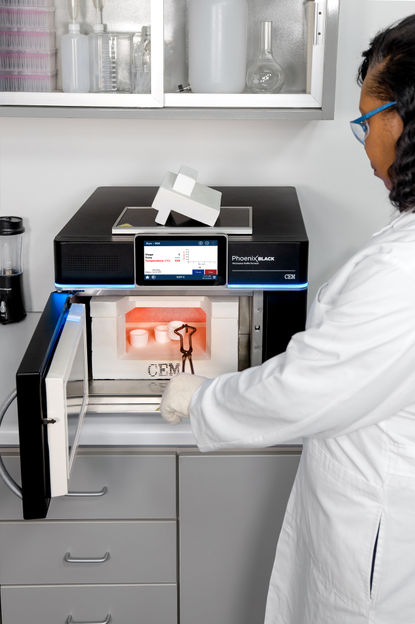

Reduce Analysis Times from Hours to Minutes

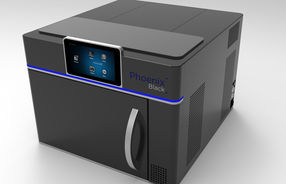

The Phönix Black™ Muffle Furnaces enable companies in many diverse industries to improve their process control, allowing them to make rapid adjustments to reduce "out-of-specification" product.

These systems can perform many high temperature applications up to 97% faster than traditional muffle furnaces. The standard Phönix Black Muffle

Furnace configuration features:

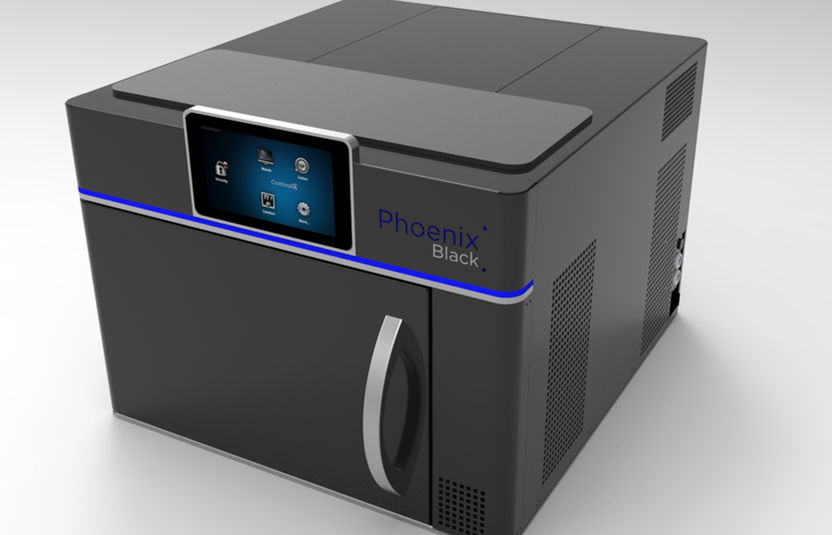

- Programmable temperature control

- Auto-Start/Auto-Shutdown software

- Built-in exhaust system

- Entry and storage of up to 20 methods

- Built-in calibration software

- Over-temperature and thermocouple failure safeguards

- Built-in system diagnostics

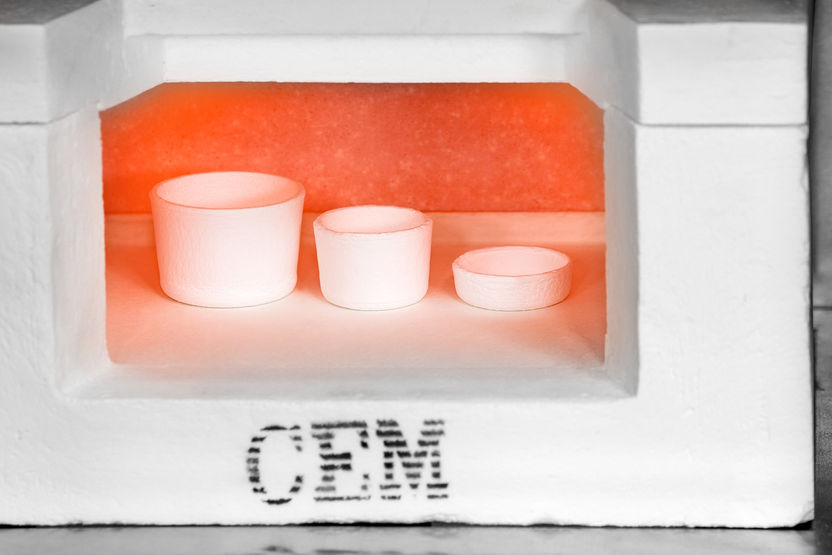

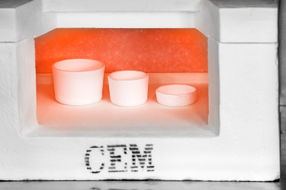

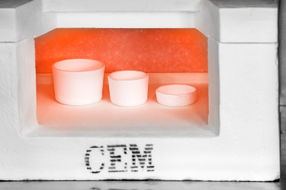

Use any type of crucible normally used in a conventional muffle furnace, including platinum!

The Phönix Systems are rugged, easy-to-use and engineered to be dependable. Temperature verification and temperature calibration for ISO and GLP practices are quickly and easily performed with optional accessories including NIST traceable dual thermocouples and calibration source instruments.

Phönix Black satisfies the equipment requirements for "electrically heated" furnaces in the following methods: ASTM, USP (281 - ROI & 733-LOI), AOAC, FDA, ISO & DIN.

Phönix Black also meets the requirements for applications listing a "microwave-heated" furnace: ASTM D5630-94, ASTM D1506-94b.

1

2

3

4

Experience this product live at the trade fair

Request information about Phoenix Black now

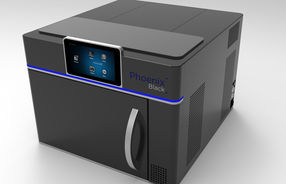

Muffle furnaces: Phoenix Black

Phönix Microwave Muffle Furnace

Product classification Phoenix Black

Product categories

Applications

Find more muffle furnaces and related products

Find Phoenix Black and related products in the theme worlds

© 1997-2026 LUMITOS AG, All rights reserved