Stirred, not struck: New riveting process from GKSS

Intensive research into new processes and materials is carried out in the transport industry and in aircraft manufacturing with the objective of reducing the weights of vehicles and airplanes. The trend in these areas is towards the use of polymer-metal hybrid structures so-called multi-material structures. Securely joining such widely dissimilar materials presents difficulties for the engineers.

GKSS employee Dr. Sergio Amancio explains: "Conventionally, these materials are adhesively bonded or mechanically fastened. For this to work, the surfaces must be usually prepared prior to joining , which can be detrimental to the environment due to chemical emissions or disposals. Additionally mechanically fastened joints experience increased stress concentrations associated with the hole placed in the joint area, which decreases mechanical performance. What's more, it takes time — and time is money."

The Institute of Materials Research at the GKSS Research Centre has acquired many years of expertise in the field of friction stir welding of metallic alloys. This technology involves pressing a non-consumable cylindrical tool with great force into two sheets of material lying next to each other and moving the tool along the weld line. The material is heated by the friction between the tool and the workpieces alone, and stirred by the tool's rotation, so that the sheets are joined. Neither special preparation of the seam nor welding additives are required.

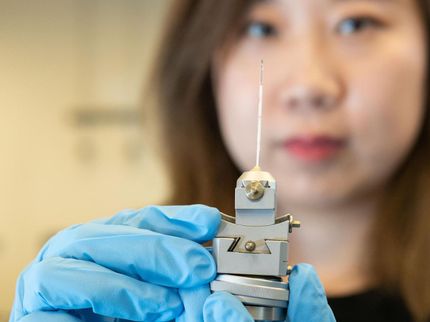

In the new Friction Riveting (FricRiveting) joining process, spot connections are produced by means of frictional heating generated by high rotational speed and pressure of a metallic consumable stud. The base materials (normally thermoplastic materials or lightweight alloys) - the joining partners - are hold together by the metallic stud. The rotating stud - the rivet - is pressed onto the surface of one of the join partners. In this initial phase, the pin penetrates into the basic material and a thin layer of molten plastic forms, which acts as an adhesive after joint consolidates.

As the rivet forces its way deeper, the frictional power increases significantly. This is generated by the increased contact force. As a result, the temperature increases and the tip of the pin spreads out assuming a higher diameter in comparison to the original rivet. This securely fixes the pin within the material (see figure). FricRiveting is capable to achieve both the positive joint properties of riveted and those of the adhesive bonding methods for polymer-metal hybrid joints: The process is reliable, saves weight and lowers production costs.

And these advantages were also recognized by the Nordmetall-Stiftung. The prize of 3,500 euros was ceremonially presented to Dr. Sergio Amancio at the traditional St. Martin's goose dinner, with more than 600 invited guests from politics and business.

Most read news

Other news from the department science

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.