New Process for Marker-free Cell Selection

At this year’s analytica trade fair in Munich, three Fraunhofer Institutes will be presenting a project from pre-competitive research. Biologists, computer scientists and laser experts have developed a process to analyze and select cells and then examine their protein production. In pharmaceutical research, this will make it possible to develop active ingredients much faster than before.

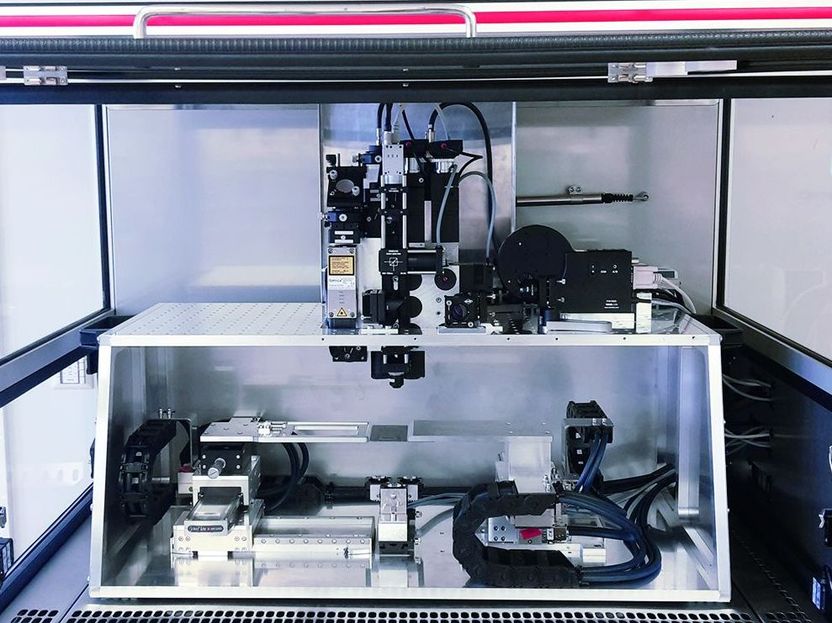

The OptisCell process is designed for fully automated operation and works without any markers or contact.

© Fraunhofer ILT, Aachen

With the new Raman LIFTSYS system (pictured here integrated into a workbench) for contact-free cell transport, various systems can be created for cell-based tests.

© Fraunhofer ILT, Aachen

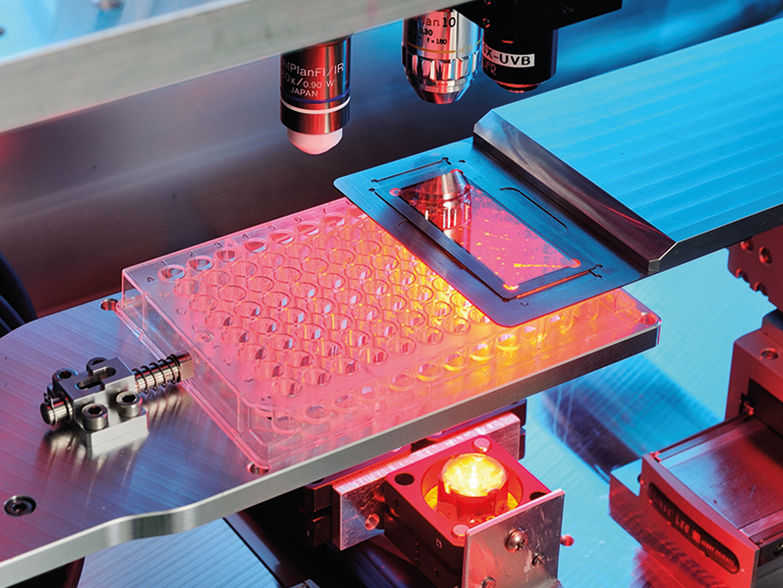

At analytica, the Fraunhofer-Gesellschaft is presenting OptisCell, a special project from market-focused pre-competitive research. In the OptisCell process, cells are identified on a carrier, then transferred using a laser pulse, and finally analyzed on a second carrier to determine their protein production.

Teams from three Fraunhofer Institutes were involved in the development work: the Fraunhofer Institute for Laser Technology ILT in Aachen, the Fraunhofer Institute for Applied Information Technology FIT in Sankt Augustin and the Fraunhofer Institute for Interfacial Engineering and Biotechnology IGB in Stuttgart.

How does the process work?

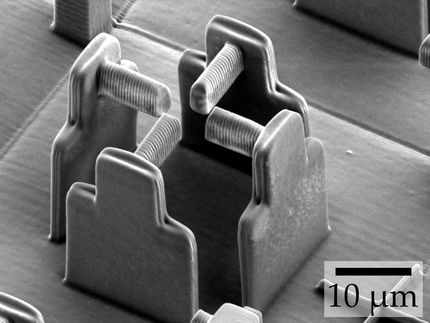

In a first step, the cells are qualitatively analyzed via Raman spectroscopy to determine whether they produce a certain protein. To do this, the system uses neural networks to distinguish the spectra of producing and non-producing cells.

In a second step, a laser pulse conveys the producing cells to a microwell plate situated opposite. Laser-Induced Forward Transfer (LIFT) is the name of the technique, whereby a laser vaporizes an ultra-thin layer of titanium on the carrier. The resulting vapor bubble generates a jet of a medium such as hydrogel, which then transfers the selected cell to the receiver plate.

In this specially prepared microwell plate, the cells are further analyzed. SERS spectroscopy is used to determine how effectively the cell produces the desired protein. This makes it possible to quickly and automatically find high-producer cells and select them for further use.

The experts at Fraunhofer ILT have already been working on the LIFT process for well over a decade. This has allowed them to successfully optimize the individual laser parameters for various transfer materials. As a result, it is possible to transfer over 80% of the cells and to transfer cells individually.

Scientists at Fraunhofer FIT developed the data management, from the initial inspection to the evaluation of protein production. To do this, they precisely documented all process steps. The system is modular and can be easily modified for other applications.

The biologists at Fraunhofer IGB manufactured special production cell lines and used them to validate the OptisCell process. To this end, they recorded a variety of Raman spectra individually and compared them against the results of conventional methods.

Application of OptisCell

The OptisCell process works without any markers or contact and is designed for fully automated operation. To validate this, the project partners built both a cell line for the production of antibodies and a system for analysis and transferring. The corresponding demonstrator will be on display at the trade fair.

Tested in antibody searching, the process will help the pharmaceutical industry in future to design development processes much more efficiently than today’s expensive, drawn-out affairs. This will reduce costs and complexity such that even SMEs will be able to carry out development work themselves.

Most read news

Topics

Organizations

Other news from the department science

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Cell Analysis

Cell analyse advanced method allows us to explore and understand cells in their many facets. From single cell analysis to flow cytometry and imaging technology, cell analysis provides us with valuable insights into the structure, function and interaction of cells. Whether in medicine, biological research or pharmacology, cell analysis is revolutionizing our understanding of disease, development and treatment options.

Topic World Cell Analysis

Cell analyse advanced method allows us to explore and understand cells in their many facets. From single cell analysis to flow cytometry and imaging technology, cell analysis provides us with valuable insights into the structure, function and interaction of cells. Whether in medicine, biological research or pharmacology, cell analysis is revolutionizing our understanding of disease, development and treatment options.

Topic World Spectroscopy

Investigation with spectroscopy gives us unique insights into the composition and structure of materials. From UV-Vis spectroscopy to infrared and Raman spectroscopy to fluorescence and atomic absorption spectroscopy, spectroscopy offers us a wide range of analytical techniques to precisely characterize substances. Immerse yourself in the fascinating world of spectroscopy!

Topic World Spectroscopy

Investigation with spectroscopy gives us unique insights into the composition and structure of materials. From UV-Vis spectroscopy to infrared and Raman spectroscopy to fluorescence and atomic absorption spectroscopy, spectroscopy offers us a wide range of analytical techniques to precisely characterize substances. Immerse yourself in the fascinating world of spectroscopy!

Trade-fair analytica

Here, innovative exhibitors present their trade fair innovations, premieres and product innovations for analytica 2026.

Trade-fair analytica

Here, innovative exhibitors present their trade fair innovations, premieres and product innovations for analytica 2026.