Spectral imager for detecting bruised fruit

The apricots on display in the supermarket look fresh when they have just arrived, but some will have developed bruises by the next day. Hyperspectral imaging allows these fruit to be identified in advance, but is expensive. Now there is a cheaper version of the technique.

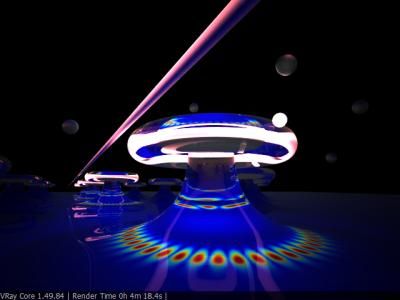

The prototype spectral imager analyzes the type of polymer in plastic bottles so that they can be sorted for recycling. The same instrument can also be used to detect bruising in fruit– before it is visible to the naked eye.

Fraunhofer IPMS / Fraunhofer-Gesellschaft

Peaches, apricots and apples have to look their best on the supermarket shelves until they a shopper has selected them and carried them to the checkout. They won’t be accepted if they are bruised. Only fruit that looks fresh and has no brown marks is good enough to be sold – blemished fruit is left on the shelf and has to be discarded. This is a challenge for suppliers, because bruising is not always visible. But these are the fruit that will start to rot only a few days later. Spectral imaging enables suppliers to detect bruising at a stage when the fruit is still edible. Damaged fruit can then be sent to manufacturers of fruit juice or yogurts for processing immediately.

The problem with spectral imaging is that the equipment is very expensive. So researchers at the Fraunhofer Institute for Photonic Microsystems IPMS in Dresden have developed a more affordable version of the spectral imager. It works in the usual way: Broadband infrared light – i.e. light made up of different wavelengths – is shone on the sample, an apricot for example. The light reflected by the sample is captured by a microscanner mirror with a superimposed diffraction grating that splits the light into its constituent wavelengths, like a prism. The detector onto which the light subsequently falls is usually 2-dimensional: It is divided up like a checkerboard, with the different wavelengths represented along one axis and the points on the surface of the inspected apricot shown along the other. IPMS business unit manager Dr. Michael Scholles explains the secret of the new imager: “Instead of being fixed in place, our microscanner mirror is movable and can deflect light of different wavelengths in different directions. This enables us to make do with a linear detector, which costs only about one tenth of the conventional type. Since the detector is the most expensive component of the imager, this makes a big difference to the price of the instrument.”

Another application for the spectral imager is sorting plastic bottles. Which are PET and which are polystyrene? The system identifies the type of polymer and thus enables the bottles to be sorted automatically. A prototype of the spectral imager has already been built. The researchers will be giving a live demonstration of the way it analyzes plastic bottles at the Electronica trade fair in Munich.

Most read news

Organizations

Other news from the department research and development

These products might interest you

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.