How good is the measurement method?

Three more interlaboratory tests on safety of chemicals

The causes of accidents can be diverse, whether it is an explosion in a chemical plant or a fire on a dangerous goods freighter. Prevention starts in the laboratory where chemicals are tested for their hazardous properties. safety experts, haulage contractors or traders must be able to rely on correct results of safety tests and assessments. Interlaboratory tests are a means of assessing the reliability of measurement results. Therefore, the Bundesanstalt für Materialforschung und -prüfung (BAM) and its partners Physikalisch-Technische Bundesanstalt (PTB), Braunschweig, and QuoData GmbH Quality & statistics, Dresden, are starting three more interlaboratory tests.

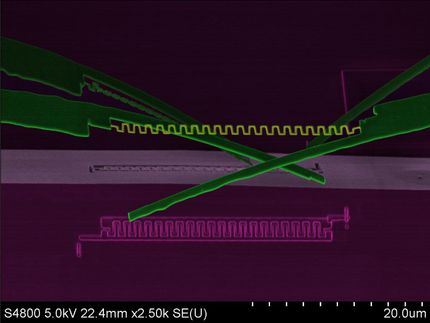

UN Test N.5 Test apparatus to evaluate gas evolution

BAM

The properties of hazardous substances and dangerous goods must be known in order to be able to assess the risks involved in their proper handling. To do this, test methods have been developed which are applied globally; however, many of the method descriptions are ambiguous. "We need to know exactly how good the method is that is used to classify dangerous goods or hazardous substances. One can certainly choose simple methods with large error limits, but these errors must be known and communicated. This would allow safety professionals to be able to assess test results correctly and make well-founded decisions," says Dr. Peter Lüth, scientist in Division 2 Chemical Safety Engineering of BAM, who is the responsible head of the interlaboratory test program.

Mr Lüth launched the first interlaboratory test for the classification of the physical hazards of chemicals 10 years ago. A success story because today around 90 laboratories participate in these interlaboratory tests worldwide. BAM, PTB and QuoData GmbH Quality & Statistics have now established a common centre of excellence for quality assurance, CEQAT-DGHS, for testing dangerous goods and hazardous substances.

Three new interlaboratory tests for methods validation are currently being prepared and will be carried out in 2017 to 2018. These are test methods for corrosion to metals (UN Test C.1), for substances which in contact with water emit flammable gases (UN Test N.5) and determination of the lower explosion limit of gases.

“Interlaboratory tests can show how suitable the method is and whether all laboratories come to the same result. Relying only on the experience of a single analyst, does not mean that the measurements are correct. Controlling capabilities through training, education, reference materials or interlaboratory tests, quality assurance of workflows helps to detect and avoid errors. Thus, we create high safety standards in technology and chemistry", says Lüth.

Most read news

Other news from the department business & finance

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.