50 years of image analysis

A room full of electronics - from QTM A to LAS 4.2

Fifty years ago the development of modern image analysis began. These early systems used to fill a whole room with electronics, very different from today’s elegant, distinctive desktop set-up. In 1962, the first automated system for the analysis of microscope images was developed by the Cambridge-based Metals Research Company. The name of the model, “QTM A”, stood for Quantitative Television Microscope, as the system employed a TV camera as signal input. Long before the invention of floppy disks or USB sticks, the QTM A was exclusively hardware-based and thus completely analog - but quite fast, considering: At a speed of 20 milliseconds per image, the grandfather of image analysis could easily keep pace with modern instruments. The initial acceptance of the concept spurred the development of QTM B as the first commercially successful automated instrument in this field.

QTM B

Leica Microsystems

Product Manager Geoff Jenkinson has been with Leica Microsystems for 40 years and has experienced the development of image analysis first hand.

Who were the customers who bought the QTM A or its successor, the QTM B, for the price of a small house?

Jenkinson: One of the first customers was the British Steel company in England. Most of the users came from the steel industry – Krupp in Germany, for example – or from metallurgic and mineralogical research institutes. These image analysis systems were mainly used for scientific purposes. Our colleagues in Marketing often sat with customers for weeks to solve their specific research problems using the QTM. Yet these first systems were extremely user-friendly. All the controls were easy to reach, and as they were all based on hardware there were no hidden menus, no computer to boot up, no software that had glitches or went out of date… You just had to turn a knob, read the results and jot them down in the lab book – really simple!

What was it like working at the dawn of a new era?

Jenkinson: We all had to think as entrepreneurs, which had a lasting effect on us. The R&D team consisted of mechanical and electronic engineers with a highly innovative mindset. We also had our own on-site patent lawyer. Application Specialists came from the same fields as our customers, i.e. materials science and increasingly life sciences, so they could talk to customers in their own terminology. It’s amazing how many of my colleagues set up their own successful companies later or became R&D managers of other companies.

Can you name some of the milestones on the road from QTM A to today’s LAS?

Jenkinson: The next milestone was the launch of the Quantimet 720 in 1969, as this marked the beginning of digitization in image analysis. A resolution of 896 x 704 pixels was achieved using special tube lens cameras and the entire image was digitized. Remarkably, the introduction of computers initially had the effect of slowing down the image analysis process. This was because early computers were unable to digest and process the vast amount of data in an image.

In the eighties, computers became cheaper and more efficient. Although the actual image processing was still done by the hardware, the microprocessors enabled images and results to be stored. The Quantimet 800 was developed using the first Apple II computer imported into England. It was delivered to my garage one memorable Friday evening.

In the following years, computer technology and image analysis developed at the same breathtaking rate. The first image analysis product that was totally independent of special hardware was the Leica QWin software. The focus in the years after that was on the development of application-specific solutions: for material science, cytogenetics, fluorescence, pathology.

Version 4.2 of the Leica Application Suite is now on the market. What are the latest trends in image analysis?

Jenkinson: Interestingly, we have reverted to the simplicity of the first instruments with the LAS Live Image Builder. Does the image need focusing? Just turn the focus control and the entire image is focused on the large modern screen. Does the field of view need extending to see the whole component? Just move the sample stage in the XY axis and the image is built up.

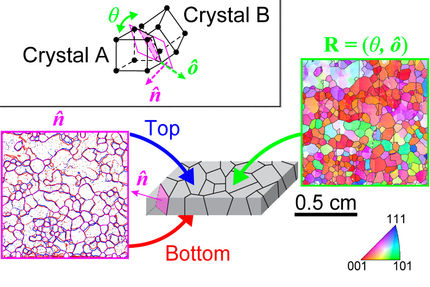

With the latest version, LAS 4.2, Leica Microsystems has continued to extend its important metallographic application portfolio: Leica Dendrite Expert examines crystalline structures in metals and alloys, while Leica Decarburisation Expert analyzes carbon loss in steel samples.