Reaction calorimetry in microreactors

At Achema 2018 the Fraunhofer Institute for Chemical Technology will demonstrate the latest gen-eration of continuous reaction calorimeters. These permit rapid screening of thermokinetic data, making kinetic constants and safety-relevant data available in the early stages of process development.

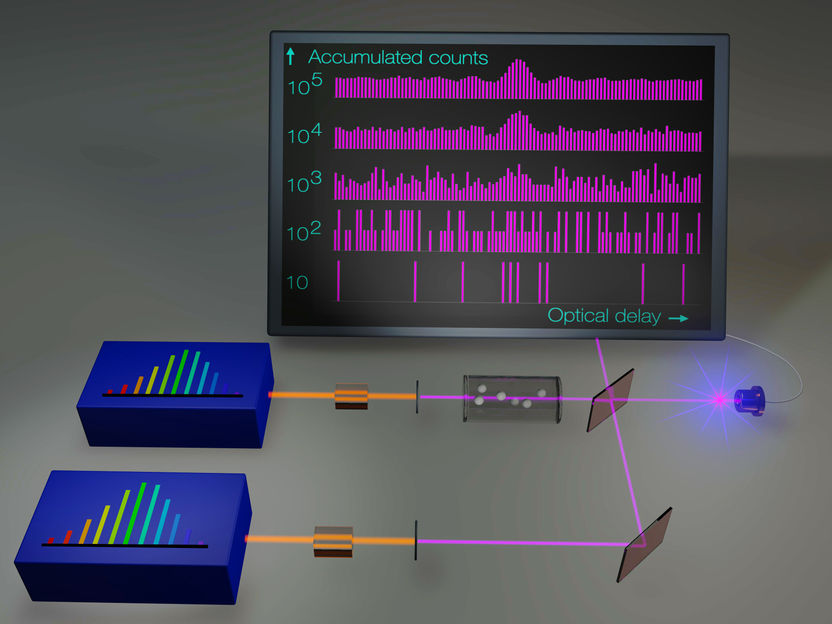

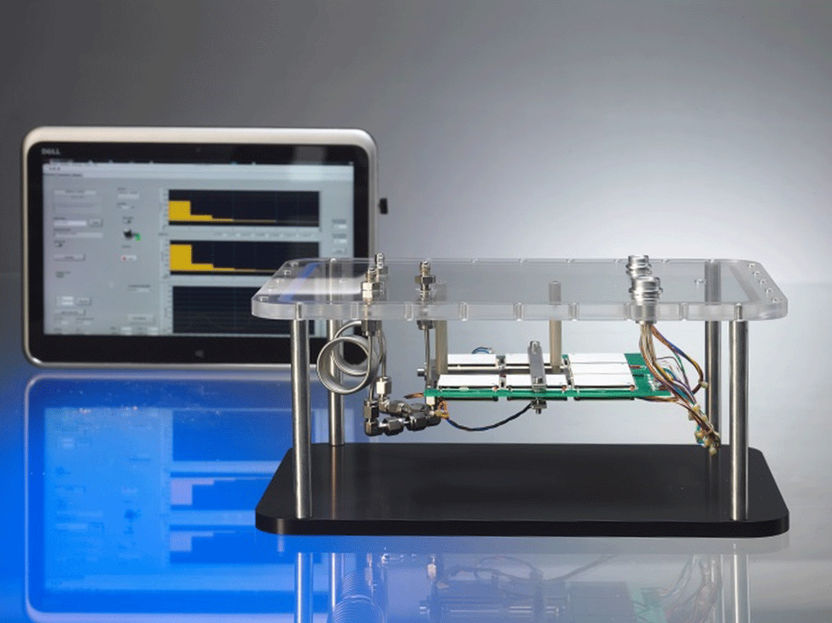

Temporally and locally-resolved reaction calorimetry in continuous reactors. The meas-urement software, which was developed on the basis of LabVIEW, enables the graphical visualization of the measured heat flows.

Fraunhofer ICT

Process design aims to develop quick, cost-effective and safe manufacturing processes in terms of synthesis, refinement and waste management. Global competition and innovation pressure predefine a limited timeframe for the development of new chemical processes. Especially in the field of specialty and fine chemistry, a significant shortening of the time-to-market is of pivotal importance for market success.

High-performance tool for process development and optimization

Fraunhofer ICT develops continuous reaction calorimeters based on microreactors, which permit the rapid screening of thermokinetic key data. The core component of the calorimeters are sensor arrays based on Seebeck elements for the localized characterization of heat flows. The sensor arrays consist of up to 40 individual sensors, which can measure the reaction heat generated in a microreactor with a high degree of temporal and spatial resolution. A variety of process parameters can be tested within a short timeframe, and their influence on the heat generation and thermal conversion can be investigated. During parameter screenings, the influence of individual process parameters (e.g. concentration, stoichiometry, use of alternative reactants, temperature, residence time, etc.) on the reaction rate can be followed directly by observing the altered heat signal – both in a qualitative and quantitative manner. In addition, even “worst-case” processing conditions can be investigated and analyzed quantitatively in terms of their energetic potential.

Flexible and high-performance

The smallest test volumes are extremely small (< 100 μl), so the consumption of substances is reduced to a minimum, which is particularly important in the case of cost-intensive chemicals. The modular design of the measuring system also permits the adaptation of the sensor arrays to a variety of reactor types and sizes. Reaction temperatures range from -80°C to +200°C and a pressure of 100 bar enables the safe investigation of new process windows.

The continuous reaction calorimeter and its applications, ranging from real-time measurement of the reaction rate through to safety investigations, are presented at the joint stand of the Fraunhofer-Gesellschaft.

Most read news

Topics

Organizations

Other news from the department science

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

On Track to Find the EHEC Pathogen - Analytik Jena AG develops an EHEC rapid test for mobile use

A new way to stimulate cellular recycling process

Thermo Fisher Scientific and QIAGEN N.V. Agree on Amended Terms to Acquisition Agreement - Offer price increased

New insights into the function of a risk factor for Alzheimer’s disease - Researchers decipher the structure-function relationship of the multifunctional protein clusterin for the first time

Rigaku opens Rigaku Technology Center Taiwan - Advancing regional growth through engineering and collaboration in Taiwan and beyond

Multiplexed Morse signals from cells

Lab901 and Biofortuna to collaborate on automated PCR Dx for HLA and Coeliac disease

Closing in on the elusive rotational-vibrational CH5+ spectra

New model predicts a chemical reaction’s point of no return - Chemists could use this quick computational method to design more efficient reactions that yield useful compounds, from fuels to pharmaceuticals

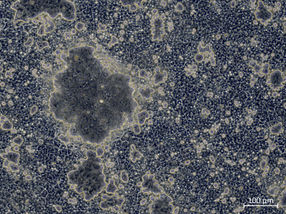

Fondant under the magnifying glass - New insights into the properties of sweet coating: The results could be used to optimize the industrial production process in the future