HYDROTHERM

Fully automatic acid hydrolysis in 90 min.

C. Gerhardt GmbH & Co. KG

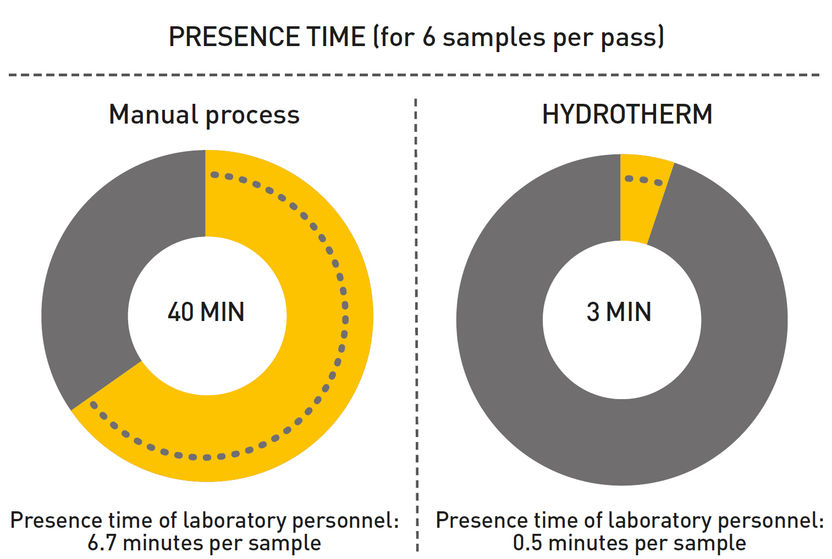

80% less work for laboratory staff

Closed system - maximum safety and no space required in the fume hood

Work according to the reference method - Validated and reproducible

Total fat determination to Weibull-Stoldt – validated for continuous operation

The time-consuming fat determination according to Weibull-Stoldt is one of the standard quality control procedures in the food industry. Reduce your laboratory staff's attendance time by up to 80% and get to know the only fully automatic hydrolysis system for classical fat determination worldwide.

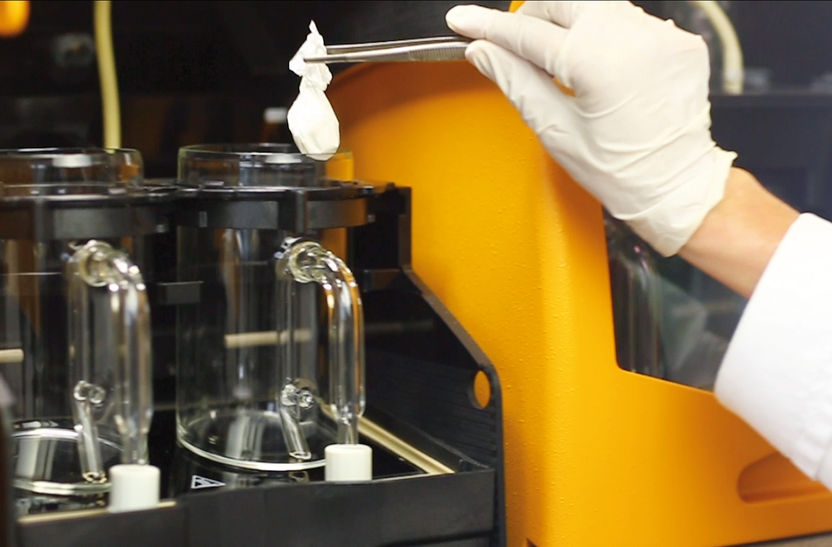

Insert sample, renew folded filter, close flap and start process - the rest is fully automatic. The HYDROTHERM takes care of the control, filtration and monitoring of the hydrolysis process for you, leaving your laboratory staff free to focus on other tasks. It doesn't matter whether you want to hydrolyse solid, liquid, homogeneous or inhomogeneous food or feed samples, everything is no problem for the HYDROTHERM.

Together with the SOXTHERM automatic rapid extraction system, which has been tried and tested for decades, the HYDROTHERM forms the only fully automatic system solution for total fat determination on the market globally.

1

HYDROTHERM: Automatic acid hydrolysis for total fat determination

2

Excellent operating safety: the entire process take place in an enclosed system. No contact with hot acids and acid fumes

3

High quality of analysis: the apparatus provides precise, completely documented and exactly reproducible digestion

4

Excellent flexibility: can be used with almost all sample types. Sample weights of 1 to 20 g for solid samples and up to 50 ml for liquid samples

5

Great savings in working time and costs

Request information about HYDROTHERM now

Acid hydrolysis systems: HYDROTHERM

Fully automatic acid hydrolysis in 90 min.

Product classification HYDROTHERM

Product categories

Applications

Manufacturers of similar products

Find HYDROTHERM and related products in the theme worlds

Topic World Food Analytics

Food analysis methods enable us to investigate the quality, safety and composition of our food. Whether in the traceability of food, the detection of contaminants or the verification of nutritional information - food analytics plays a crucial role in our health and nutrition. Welcome to the exciting world of food analytics!

Topic World Food Analytics

Food analysis methods enable us to investigate the quality, safety and composition of our food. Whether in the traceability of food, the detection of contaminants or the verification of nutritional information - food analytics plays a crucial role in our health and nutrition. Welcome to the exciting world of food analytics!