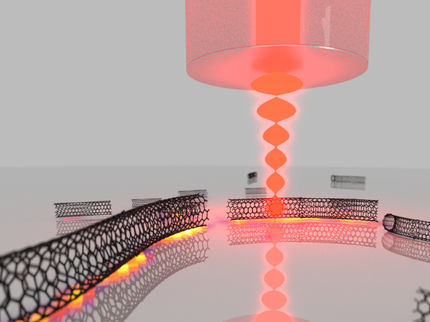

Using optical fiber to generate a two-micron laser

In recent years, two-micron lasers (0.002 millimetre) have been of growing interest among researchers. In the areas of surgery and molecule detection, for example, they offer significant advantages compared to traditional, shorter-wavelength lasers. However, two-micron lasers are still in their infancy and not yet as mature as their telecom counterparts (1.55-micron). Moreover sources currently used in labs are typically bulky and expensive. Optical fibre-based 2 micron lasers are an elegant solution to these issues. This is where researchers at photonics Systems Laboratory (PHOSL) come in.

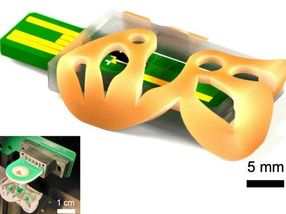

The team of Camille Brès at EPFL described a way to design these lasers at a lower cost, by changing the way optical fibres are connected to each other. Thanks to the new configuration, they were able not only to produce very good 2 micron lasers, but also to do without an expensive and complex component that is normally required.

Bloodless surgery and long-range molecule detection

Two-micron spectral domain has potential applications in medicine, environmental sciences and industry. At these wavelengths, the laser light is easily absorbed by water molecules, which are the main constituents of human tissue. In the realm of high precision surgery, they can be used to target water molecules during an operation and make incisions in very small areas of tissue without penetrating deeply. What is more, the energy from the laser causes the blood to coagulate on the wound, which prevents bleeding.

Two-micron lasers are also very useful for detecting key meteorological data over long distances through the air. Not to mention that they are highly effective in the processing of various industrial materials.

Replacing a cop with a detour

To create a 2 micron fibre-laser, light is usually injected into an optical-fibre ring containing a gain region which amplifies 2 micron light. The light circulates in the ring, passing through the gain region many times thus gaining more and more power, until becoming a laser. For optimal operation, these systems include a costly component called isolator, which forces the light to circulate in a single direction.

At PHOSL, researchers built a thulium-doped fibre laser that works without an isolator. Their idea was to connect the fibres differently, to steer light instead of stopping it. "We plug a kind of deviation that redirects the light heading in the wrong direction, putting it back on track", said Camille Brès. This means no more need for the isolator, whose job is to stop light moving in the wrong direction, sort of like a traffic cop. "We replaced the traffic cop with a detour," said Svyatoslav Kharitonov, the article's lead author.

Higher quality laser

The new system not only proved to be less expensive than more traditional ones, it also showed it could generate a higher quality laser light. The explanation is as follows: the laser output gets purified because light interacts with itself in a very special way, thanks to the amplifying fibre's composition and dimensions, and the high power circulating in this atypical laser architecture. "While the association of amplifying fibres and high power usually weakens traditional lasers performance, it actually improves the quality of this laser, thanks to our specific architecture", said Svyatoslav Kharitonov.

Original publication

Other news from the department science

Get the analytics and lab tech industry in your inbox

From now on, don't miss a thing: Our newsletter for analytics and lab technology brings you up to date every Tuesday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.